Cnc Laser

StarFiber Series combines compact fiber lasers with optional cutting heads or focusing heads for laser welding and cutting. SmartWeld(tm), which allows for fine and broad welds, is also available.

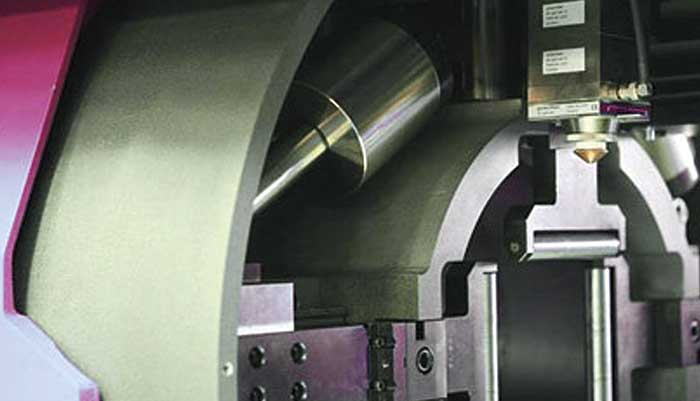

Laser system that combines sheet and tube metal cutting. Tubes upto O 4.72" (120mm).Sheets upto 236"x79" (6000mm x 2000mm)Fiber Laser